Wire mesh manufacturer:Provide customized product services

Email Gary@kindwiremesh.com Mobile +86-18631872999What issues should be noted when accepting stainless steel welded mesh?

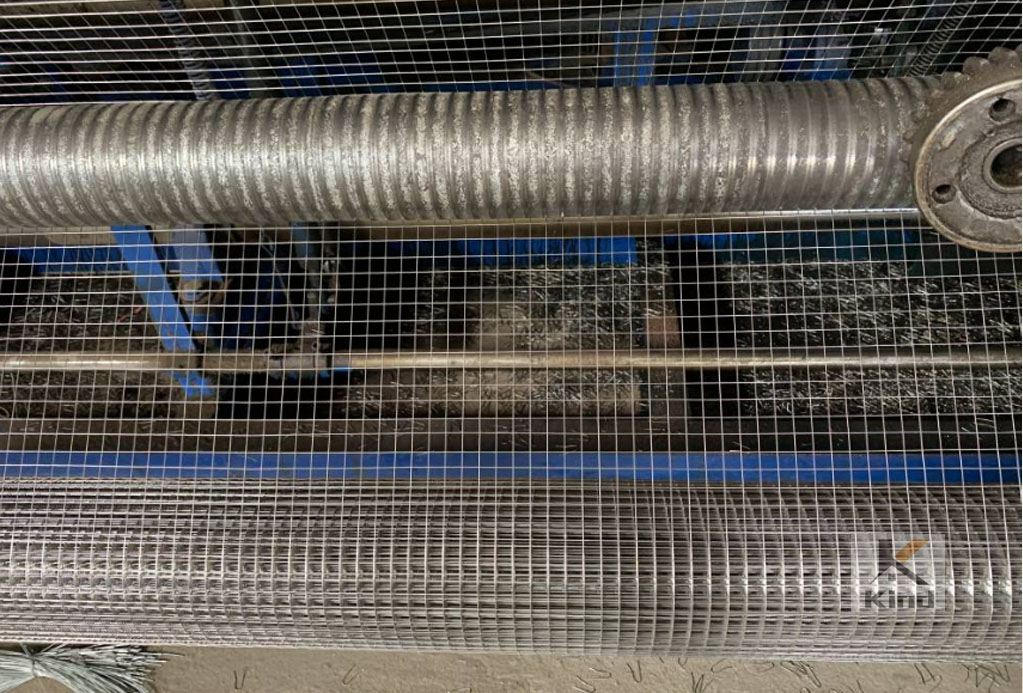

There are many types of materials for stainless steel welded wire mesh, one is cold drawn steel wire, and of course, there are other materials such as galvanized wire, hot-dip galvanized wire, and drawn wire. Surface treatment: hot-dip galvanizing, cold dip galvanizing, spray coating. Vibrant mesh materials are widely used in exhibitions, sample racks, and more.

How should stainless steel welded wire mesh be inspected for these raw materials before making the mesh? Below is a brief introduction for everyone, hoping to be helpful. Before cold drawing stainless steel welded wire mesh, check each indicator or use a dynamometer to confirm correctness before using steel wire. And keep records during use. After completing it twice, we should check if there are any cracks or partial necking on the surface. After the cold drawing process, the surface of the steel wire is prone to rust, and rust prevention work should be done well. During the use of stainless steel welded wire mesh, the cold drawing speed should not be too fast. The belt should be pulled to the specified length or the specified control stress before stopping. If the welded joint breaks, it can be cold drawn no more than twice after re welding. The inspection of stainless steel welded mesh should be completed before acceptance, without cracks or mechanical damage. The above is the relevant content of stainless steel welded mesh, hoping to be helpful to everyone.